RV-K cable is a type of cable commonly used in a variety of industrial, commercial and residential applications. It is known for its excellent electrical performance, durability and resistance to harsh environmental conditions. When selecting an RV-K cable for a particular application, it is important to understand the different sizes and gauges available as they can have a significant impact on the performance of the cable.

RV-K cable size

The size of the RV-K cable refers to the cross-sectional area of the inner conductor of the cable. Conductors are the wires that carry electricity through the cable. The size of the conductor affects the amount of current the cable can carry without overheating or causing other problems. Fire resistant cables are available in a variety of sizes, from small wires with a cross-sectional area of a few square millimeters to large cables with a cross-sectional area of several hundred square millimeters.

The most common sizes for RV-K cables are 1.5mm², 2.5mm², 4mm², 6mm², 10mm², 16mm², 25mm², 35mm², 50mm², 70mm² and 95mm². Each size is designed to handle a specific amount of current, with larger sizes capable of carrying more current than smaller sizes. The cable size required for a particular application depends on the amount of current flowing through the cable, as well as the length of the cable and other factors.

RV-K Cable Specifications

In addition to size, RV-K cables have a range of specifications that affect their performance. Some of the most important specifications to consider when selecting an RV-K cable include:

- Rated Voltage: Rated voltage ranges from 300V to 1000V. The voltage rating indicates the maximum voltage that the cable can safely handle without failing or causing other problems. It is important to select a cable with the proper voltage rating for the application.

- Temperature Rating: Designed to operate in temperatures ranging from -40°C to +90°C. The temperature rating indicates the highest and lowest temperatures the cable can safely handle without degrading performance or causing other problems. It is important to select a temperature rated cable suitable for the application.

- Conductor Material: Conductors are available in a variety of materials including copper and aluminum. Copper conductors are generally preferred because of their excellent electrical conductivity and corrosion resistance, but aluminum conductors are often used in applications where weight is a concern.

- Insulation Material: Insulated with a variety of materials including PVC, XLPE and EPR. Insulation materials affect a cable’s flexibility, durability, and resistance to heat, moisture, and other environmental factors.

Factors to Consider When Selecting RV-K Cable Size and Gauge

- Environmental Factors: Designed to withstand a range of environmental factors including moisture, UV radiation and chemicals. It is important to select a cable with insulation and jacket materials suitable for the specific environmental conditions in which it will be used.

- Electrical Requirements: The amount of current flowing through the cable as well as the voltage and frequency of the electrical system are important factors to consider when selecting RV-K cables. It is important to select a cable that meets the specific electrical requirements of the application.

- Other Considerations: Other factors to consider when selecting cables include cable length, installation method, and maintenance requirements. It is important to select cables that are suitable for specific installation and maintenance conditions.

What are the most common installation methods for RV-K cables?

- Surface Mount: This method involves running the RV-K cable along the surface of a wall, ceiling, or other structure. Cables are usually secured with clips or conduit, often in situations where it is not possible to mount the cable inside a wall or other structure.

- Conduit: Installing RV-K cables in conduit involves placing the cable inside a protective tube made of metal or plastic. Catheters provide additional protection against physical damage or environmental elements such as moisture or UV radiation. This method is typically used in areas where cables are exposed to the elements or are at risk of damage from other sources.

- Direct Burial: This method involves burying the RV-K cable directly into the ground without the use of conduit. This is a common installation method for outdoor lighting or other applications where the cables are exposed to the elements. The cable is usually buried to a depth of at least 18 inches to protect it from physical damage.

- Underfloor: This method involves installing the cables under the floor of the building. Cables are usually placed in protective conduit or trunking to protect them from damage. This method is often used in commercial or industrial buildings where it is important to keep cables hidden.

- Tray: This method involves installing the RV-K cable in a cable tray, which is a metal or plastic structure designed to support and protect the cables. Trays are typically mounted to the wall or ceiling, with cables secured to the tray using cable ties or other fasteners. This method is often used in industrial or commercial settings where large numbers of cables need to be organized and supported.

In conclusion

The RV-K cable is a versatile and reliable cable with a wide variety of applications. When selecting a cable for a particular application, it is important to understand the different sizes and gauges available, as well as the environmental, electrical, and other factors that can affect cable performance.

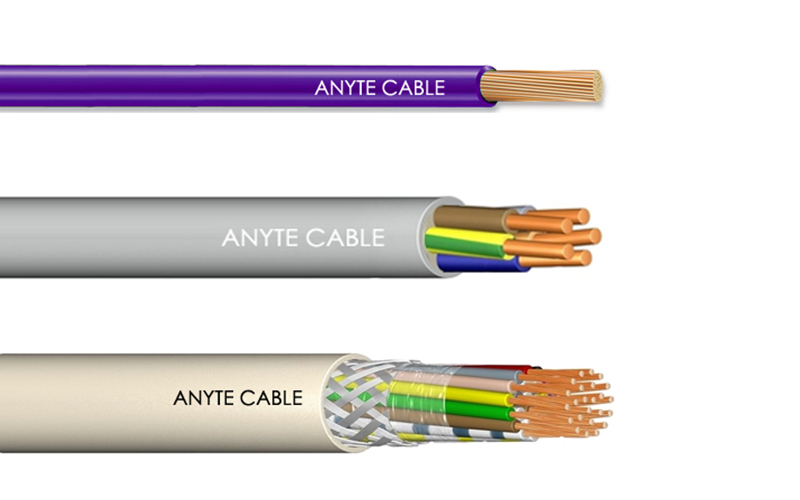

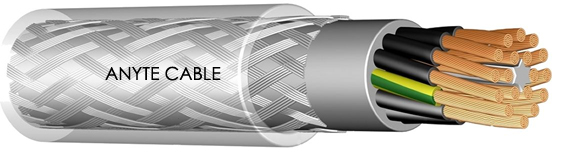

Anyte Cable is a reputable cable manufacturer that takes the quality and reliability of their products very seriously. In particular, they rigorously test cables such as RV-K to ensure they meet the highest standards and requirements for fire rated cables. In addition to focusing on technology, Anyte Cable also places great emphasis on providing international services. This means that their products are not only designed to meet the specific requirements of the German market, but also comply with international standards and regulations. Providing versatility and compatibility by meeting the needs of global customers and ensuring that its cables can be used in different applications and industries around the world. If you have any needs, please feel free to consult!

Related Products