UL2464 cable is a multi-conductor cable commonly used in a variety of applications, including computer, data processing, and control systems. It is known for its excellent electrical performance, durability and resistance to environmental elements.

Installation requirements

Proper installation is critical to the safe and reliable operation of UL2464 cables. Some of the most important installation requirements for UL2464 cables include:

1. Choose the right installation method: Various installation methods can be used, including surface installation, conduit or direct burial. Selecting the proper installation method depends on factors such as environmental conditions, physical stress and accessibility to the installation site.

2. Select the proper cable size and type: Selecting the proper cable size and type depends on the electrical requirements of the specific application. It is important to select a cable size and type that can handle the required electrical load without exceeding its current carrying capacity.

3. Proper routing and spacing: Proper routing and spacing should be used to prevent damage or interference from other cables or equipment.

4. Correct grounding: should be properly grounded to prevent electric shock or damage to equipment.

5. Comply with local regulations: It is very important to comply with all local regulations related to the installation of UL2464 cables to ensure their safe and legal operation.

Maintenance requirements

Proper maintenance is essential to ensure the safe and reliable operation of UL2464 cables throughout their useful life.

1. Routine Inspection: UL2464 cables should be inspected periodically for wear, damage, or other issues that may affect their performance.

2. Cleaning: It should be cleaned regularly to remove any dirt, dust or other debris that may affect its performance.

3. Maintenance: Any problems found during daily inspection or cleaning should be repaired in time to prevent further damage to the cable.

4. Replacement: The cable should be replaced when it has reached the end of its useful life or is damaged beyond repair.

Security considerations

Appropriate safety measures should be taken when working with cables to prevent the risk of electric shock and fire. Some of the most important safety considerations for UL2464 cables include:

1. Correct grounding: It should be grounded correctly to prevent electric shock or damage to the equipment.

2. Proper insulation: It should be properly insulated to prevent electric shock or damage to the equipment.

3. Safe work practices: Workers should follow safe work practices when using UL2464 cables, such as wearing appropriate personal protective equipment and using proper tools and equipment.

4. Comply with local regulations: It is important to comply with local regulations related to the installation and maintenance of all cables to ensure their safe and legal operation.

UL2464 cable is a durable and reliable cable designed to withstand a variety of environmental elements and physical stress. However, it can still be damaged under certain conditions. Some of the most common causes of cable damage include:

- Physical stress: Physical stress such as bending, twisting or crushing can damage the cable’s insulation and expose the conductors to the environment. This can result in degraded electrical performance and, in some cases, an electric shock or fire hazard.

- Environmental factors: Environmental factors such as moisture, heat and chemicals can damage the insulation of the cable and expose the conductors to the environment. This can result in degraded electrical performance and, in some cases, an electric shock or fire hazard.

- Improper Installation: Improper installation, such as using the wrong mounting method or failing to properly ground the cable, can damage the cable and result in reduced electrical performance, electric shock, or fire hazard.

- Corrosion: Corrosion, such as rust or oxidation, can damage a cable’s conductors or insulation and cause loss of electrical performance or a shock hazard.

- Age: Like all materials, cables will age over time due to normal wear and tear. As a cable ages, its insulation may become brittle, crack or break, resulting in reduced electrical performance or a shock hazard.

- Electrical Surges: Electrical surges such as lightning strikes or power spikes can damage the conductors or insulation of a UL2464 cable and cause electrical degradation or a fire hazard.

It is important to take steps to prevent or minimize the risk of cable damage by following proper installation and maintenance procedures, selecting the proper cable size and type for a specific application, and complying with all local codes and regulations. Regular inspections, cleanings, and repairs can also help identify and fix potential problems before they become major problems.

In conclusion

Proper installation and maintenance are critical to the safe and reliable operation of UL2464 cables. When installing cables, it is important to choose the proper installation method, cable size and type, and to follow all local codes and regulations. When maintaining a Fire resistant cable, it is important to perform routine inspections, cleaning and repairs, and to replace the cable when it reaches the end of its useful life.

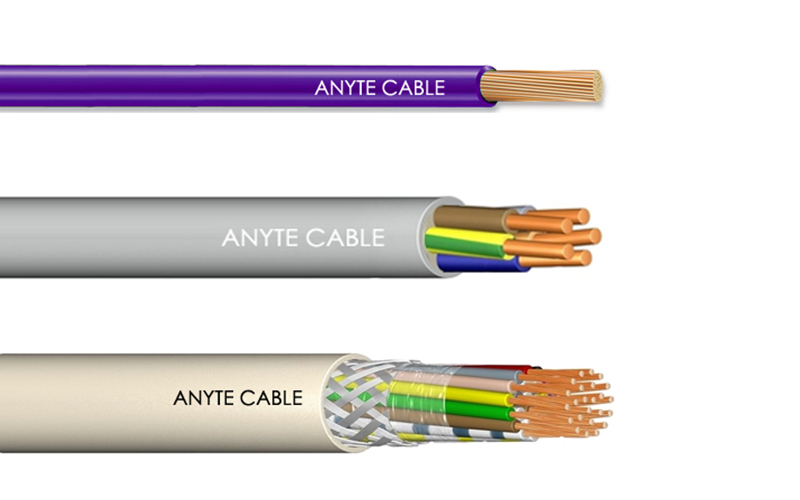

Anyte Cable not only develops and manufactures standard high-quality cables, but also provides excellent solutions according to your needs and product applications. Welcome your inquiry at any time.

Related Products

AWM UL2464