Ⅰ. Introduction

NHXH cable is a low-smoke halogen-free power cable. Low smoke reduces the generation of harmful objects during combustion. Halogen is a toxic gas for the human body. Halogen-free means that there is no release of toxic gas. It is usually used for cables in case of fire. in terms of time. Low-smoke and halogen-free power cables can also be called environmental protection cables. Most of the low-smoke and halogen-free cables are used in hospitals and places with strict environmental hygiene requirements.

With the development of flame retardant technology for cable materials, new types of flame retardant cables are constantly being produced. For example, NHXH cable has developed from the original ordinary flame retardant cable to low smoke and low halogen flame retardant cable and low smoke and halogen free flame retardant cable. This shows that in recent years, the requirements for flame retardant cables are getting higher and higher.

The earlier use of polymeric materials to enhance the flame retardant properties of cables poses a serious fire hazard in the event of a fire. These added substances emit smoke, which is highly toxic and corrosive when exposed to fire. Halogens released from fire exposure tend to react with hydrogen and form hydrogen halides.

Additionally, when these hydrogen halides are mixed with water, they form toxic acids that can cause catastrophic damage to the entire cable infrastructure. Cables containing halogenated materials are also responsible for the formation of carbon monoxide (CO) gas during combustion, which further increases the risk. The use of LSZH cables eliminates such risks and provides increased safety against any catastrophic damage.

Ⅱ. NHXH cable low smoke halogen free power cable features

- Low-smoke halogen-free wire has high fire resistance, anti-aging, long life and good safety performance.

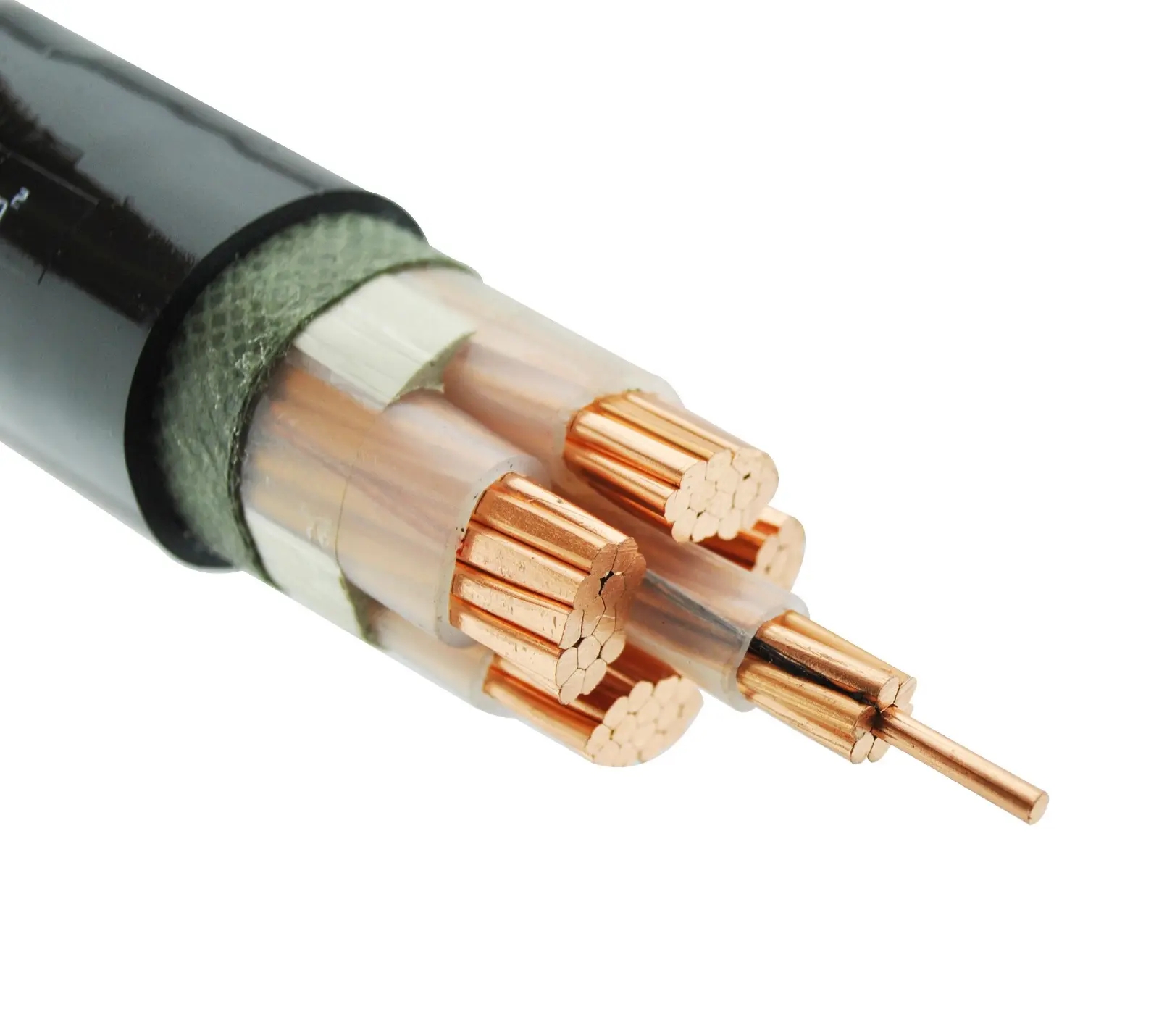

- Special flame retardant wire, with a layer of coating on the copper core, to increase the electrical conductivity, and the load is large.

- Using low-smoke halogen-free materials, and adding special flame retardant ingredients, high flame retardant, low smoke.

Ⅲ. Extrusion equipment

- The main component of wire and cable extrusion equipment is the screw, which is related to the application range and production efficiency of the extruder. In order to meet the needs of different plastic processing, there are many types of screws. Low-smoke halogen-free flame retardant cable material Contains highly filled magnesium hydroxide or aluminum hydroxide, so for the selection of the screw, the ordinary screw is generally used and its compression ratio should not be too large, generally between 1:1 and 1:2.5 is more appropriate.

- There is also an important factor affecting the extrusion of low-smoke halogen-free cables during the extrusion process, that is, the cooling device of the extruder. Large heat, which requires the extrusion equipment to have a good cooling device in order to control the process temperature.

Ⅳ. NHXH cable low smoke halogen free power cable identification

1. Combustion method

According to whether the material is easy to burn, judge whether it is NHXH cable or flame-retardant power cable CE NHXH, according to whether it burns, identify its flame color; whether it emits smoke, and how much smoke is generated, whether it is a low-smoke halogen-free power cable. Identify the color of the smoke, such as: whether the smoke is clear smoke or smoke containing charcoal ash; whether there is sol dripping, if so, see whether the sol continues to burn; and what kind of odor is produced when burning.

2. Specific gravity method

The density comparison method is based on the density of water. The plastic material is placed in water. If it sinks, the density of the plastic is higher than that of water, and if it floats, it is smaller than water. This method can be used in conjunction with other methods.

For the above two, simply test flame-retardant power cables, flame-retardant wires, low-smoke halogen-free power cables, and low-smoke halogen-free wires.

Ⅴ. NHXH cable application standard

- NHXH cable is suitable for fixed installation in dry and wet environment, above or below plaster, on cable tray, the same as in walls and concrete. Not suitable for laying directly in the ground or in water.

- For outdoor applications, it can be laid in the pipe, but in this case, all necessary precautions should be taken to prevent water from seeping into the pipe.

- Suitable for electrical installations with obvious fire protection and functional protection requirements, used in alarm systems, fire sensors, evacuation elevators and other power supply systems in emergency situations.

- Applicable to all situations where people and materials need to be protected in the event of a fire. It is recommended for public buildings with many people, as well as buildings with high material value, industrial complexes, power plants, substations, municipal facilities, hotels, shopping malls, hospitals, schools, airports, subways, etc.

- Important NHXH cables should not be laid on ordinary trays, but on fire-resistant trays to maintain their geometry in the event of a fire.

- It is widely used in large-scale engineering and high-tech fields, such as railways, subways, automobiles, etc.;

- In daily life, low-smoke halogen-free cables are widely used in nuclear power plants, telephone exchanges and computer control places, high-rise buildings, hotels, etc., radio and television stations, important military facilities and oil platforms, and places where people are relatively concentrated.

Ⅵ. NHXH cable advantages

- Halogen-free, no toxic or corrosive gas will be released in case of fire.

- Reduce the occurrence of smoke under fire.

- No flame propagation in vertical cable bundles.

- Maintain the electrical function of the system for a set time.

Anyte Cable not only develops and manufactures standard high-quality cables, but can also provide special solutions according to your needs and product applications, ensuring that all your high-quality, high-demand and high-standard cables are met, and the product life is longer than customers expect Longer, so that you have first-class product technology and international service Germany.