Ⅰ. Introduce

Safe and reliable cable selection is critical for most businesses. RV-K Power Cable can meet all safety and reliability requirements. It is characterized by strong anti-interference, strong resistance to EMI/RFI, high reliability and good durability. CE RV-K cable is a safe and reliable cable you can trust.

There are thousands of types of wire and cable products, which are used in all walks of life. There are two general uses for them, one is to transmit current and the other is to transmit signals.

The main technical performance indicators controlled by cables that transmit current are conductor resistance and withstand voltage performance; the main technical performance indicators controlled by cables that transmit signals are transmission performance—characteristic impedance, attenuation, and crosstalk. Of course, the transmission signal mainly relies on current (electromagnetic wave) as the carrier, and now with the development of science and technology, light waves can be used as the carrier for transmission.

Ⅱ. The basic structure of the cable

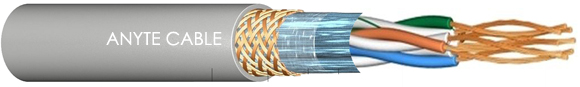

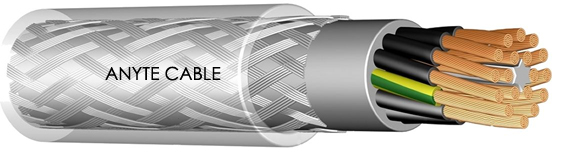

Generally, the most basic structures of cables are conductors, insulating layers and outer sheaths, and some structures are added according to requirements, such as shielding layer, inner sheathing or armoring layer, etc. Some filler materials are added for the sake of the roundness of the cable. The conductor is the carrier of current or signal, and other structures are used for protection.

For example: the performance of RV-K Power Cable protection is generally divided into three types according to the needs of cable products, one is to protect the various units of the cable itself from affecting each other or reduce the impact, the other is to protect the current in the conductor from affecting the outside, and finally One that protects the outside world from affecting the inside of the cable.

1. Conductor

Its function is to conduct current. There are solid core and stranded. The materials are copper, aluminum, aluminum alloy, silver, copper-clad steel, aluminum-clad steel, etc., and copper and aluminum are mainly used. Copper conducts electricity much better than aluminum.

2. Refractory layer

Only fire-resistant cables have this structure. Its function is that the cable can withstand a certain time in a fire, giving people more time to use electricity when escaping. The material used now is mainly mica tape. In a fire, the cable will burn quickly. Because the mica sheet of the mica tape is resistant to high temperature and has an insulating effect, it can protect the conductor from running for a certain period of time in a fire.

3. Insulation layer

Wrapped outside the conductor, its function is to isolate the conductor, withstand the corresponding voltage, and prevent current leakage.

4. Shielding layer

Outside the insulating layer, inside the outer sheath, the function is to limit the electric field and electromagnetic interference.

For different types of cables, the shielding materials are also different, mainly including: copper wire braid, copper wire winding, aluminum wire (aluminum alloy wire) braid, copper tape, aluminum foil, aluminum (steel) plastic tape, steel tape, etc. Longitudinal package and so on.

5. Fill

The function of filling is mainly to make the cable round and stable in structure. The filling of some cables also plays the role of water resistance and fire resistance. The main materials are polypropylene rope, glass fiber rope, asbestos rope, rubber, etc. There are many kinds, but there is a main performance requirement that is non-hygroscopic material, which of course cannot conduct electricity.

6. Inner sheath

The function of the inner sheath is to protect the insulated wire core from being damaged by the armor or shield.

7. Armor layer

The role of the RV-K Power Cable armor layer is to protect the cable from being damaged by external forces.

8. Outer sheath

A component that protects the outermost layer of the cable.There are three main types: plastic, rubber and metal.

Among them, the most commonly used plastics are polyvinyl chloride plastics and polyethylene plastics, and according to the characteristics of cables, there are flame retardant, low smoke and low halogen, and low smoke and halogen-free.

Ⅲ. What is the difference between RV-K Power Cable and cable RVV

①The naming method is different

RV is generally used for single-core soft electrical conductor without sheath cable, RVV polyethylene insulation layer polyethylene sheath cable and wire.

②The structure of the electrical conductor is different

RV-K Power Cable is a single-core copper wire; while RVV is a multi-core copper wire, which consists of two or more RV wires, and the order of the copper core cables is not particularly specified.

③The structure of the grommet is different

There is no protective sheath on the outside of the RV cable; while there is a layer of PVC sheath on the outside of the RVV cable. effect.

④The rated voltage is different

RV lines are rated at 450V/750V, while RVV lines are rated at 300V/500V.

⑤The main purpose is different

The RV line is suitable for flexible installation sites with strict regulations, such as electrical cabinets, power distribution cabinets and various low-voltage electrical machinery and equipment. It can be used for power engineering, electrical control system data signals and power switch data signals transmission, and is suitable for The installation site is wet, cold and oily.

Ⅳ. Characteristics of CE RV-K cables

- It has excellent withstand voltage performance and can work under rated voltage.

- The cable has good heat resistance and can work under rated voltage.

- The cable has excellent cold resistance and can be used in low temperature environment.

- The cable has superior air tightness, which can prevent the outside air from entering the inside of the cable.

- RV-K Power Cable is made of special material, which makes the cable have good UV resistance.

Ⅴ. Installation of CE RV-K cables

1. Preparations

Cable preparation First, we need to divide the cable into several sections, depending on the actual situation. Then connect the corresponding terminals. Take care to ensure that the cables are securely connected.

2. Installation of air conditioners and fans

If it is a newly installed machine, please fix the base of the machine first. Then install the fan and air conditioner above the machine. Take care to avoid interference with cables.

3. Secure the CE RV-K cable

When fixing, please use glue or wax. If using glue, open the glue first, and then fill the glue into the fixed part. Secure the CE RV-K cable again. If wax is used, soak the wax block directly into the fixation area.

CE RV-K cables can be fixed in many ways, and different methods can be adopted according to different situations.

Ⅵ. Maintenance requirements for CE RV-K cables

- When used indoors, the cables should be laid in a well-ventilated place.

- The cables shall not be laid in places with high temperature, humidity or corrosion by chemical substances.

- Cables shall not be laid in places that are prone to fire.

- Check whether the cable is damaged regularly, and repair it in time if any fault is found.

Ⅶ. Application of RV-K Power Cable

CE RV-K cables have the characteristics of high pressure resistance, good wear resistance and excellent electrical conductivity, and are widely used in various industrial and civil distribution lines. The RV-K Power Cable has a long service life and good durability, making it an ideal power distribution cable.