Introduce

In the world of electrical and electronic projects, selecting the correct components is critical to ensure optimum performance, safety and longevity. A suitable awm single core cable is one of the important components, it is a versatile cabling solution designed to meet the needs of various applications. In this article, we’ll dive into the basic considerations that must be considered when selecting the appropriate AWM single core cable for a particular project. Understanding these factors will enable engineers, designers, and project managers to make informed decisions that can contribute to project success.

Project Requirements Analysis

At the heart of cable selection lies a thorough analysis of project requirements. This initial step involves defining the project’s power needs and environmental conditions. Consider factors such as voltage, current, temperature and mechanical stress. By accurately measuring these requirements, you can lay the foundation for selecting a cable that will reliably meet the needs of your project.

Cable Performance Evaluation

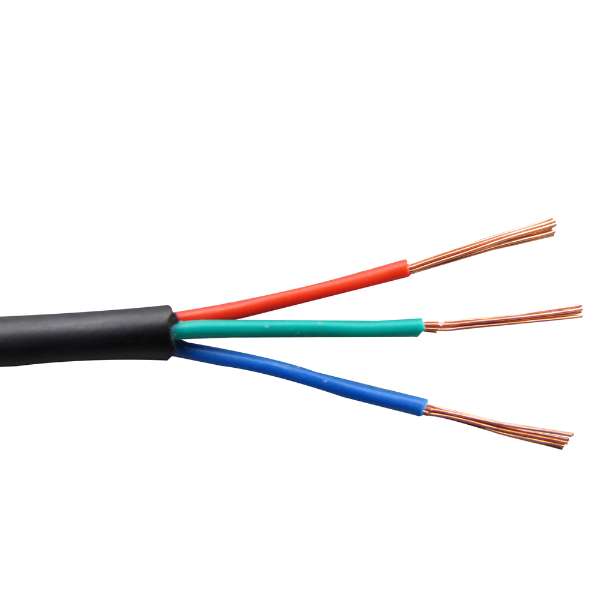

The characteristics of a suitable awm single core cable play a key role in determining its suitability for a particular project. A thorough evaluation of these characteristics ensures that the selected cable will meet the needs of the project. First, evaluate the conductor material and size. Copper is a common choice due to its excellent electrical conductivity, but aluminum may be preferable for certain applications. Insulation material and thickness are equally important as they determine a cable’s resistance to environmental factors and electrical interference.

Voltage and current ratings are basic indicators of cable performance. Exceeding these limits may result in overheating, voltage drops and even cable failure. Temperature ratings are another key factor. Different projects may require cables that can withstand different temperature ranges, from extremely cold to hot.

Flexibility and bend radii are especially important when cables need to pass through tight spaces or move frequently. Neglecting these aspects can cause mechanical stress on the cable, which can lead to premature wear.

Cable application and environment

The intended application and environment have a major impact on the choice of awm single core cable. Indoor and outdoor applications have different requirements. Outdoor cables must be able to withstand elements such as moisture, UV radiation and chemicals. Fixed installations require cables that are durable and will not degrade, while cables subject to dynamic movement require enhanced flexibility and durability.

In addition, environmental conditions such as ambient temperature, vibration, and electromagnetic interference should be thoroughly evaluated. Certain cables are designed to perform well in high vibration environments, ensuring signal integrity remains intact.

Compliance and Regulations

Compliance with industry standards and regulations is not just a legal requirement; it is a legal requirement. It is an integral part of ensuring safety and reliability. AWM cables are classified according to their compliance with specific standards, and selecting the proper category is critical. Verify that the selected cable complies with the relevant codes and certifications for your industry and jurisdiction. This step reduces the risk of potential legal and security issues.

voltage drop and power loss

Voltage drops can have a significant impact on the performance of your project. When current flows through the cable, the voltage will naturally drop due to the resistance of the cable. It is important to calculate the expected voltage drop based on the cable length and current load. Selecting cables with lower resistance mitigates voltage drop and minimizes power loss, ensuring that equipment receives the voltage it needs to operate optimally.

budget constraints

While striving for the best quality is admirable, budget constraints must be considered when choosing an awm single core cable. Finding the balance between cost-effectiveness and performance is key. While higher-quality cables may come with a higher upfront cost, they often provide long-term savings through reduced maintenance and replacement needs.

Future expansions and upgrades

Anticipating future needs and potential expansion is a sign of a well-ready project. Choosing cables that can future-proof without major repairs saves time and resources. This consideration is especially important for industries with rapidly evolving technology and infrastructure.

Supplier and Manufacturer Reputation

The reputation of cable suppliers and manufacturers cannot be ignored. Choose a well-known and reputable supplier known for quality and reliability. A reliable supplier will not only provide high-quality products, but also provide excellent customer support and after-sales service.

Safe and reliable

Most importantly, safety and reliability are paramount. AWM single-core cables should have proper insulation and fire resistance to ensure the safety of the project and its surroundings. Reliable cables contribute to the overall stability and durability of the system, reducing the risk of costly downtime and repairs.

In conclusion

Selecting the right awm single core cable for your project is a multifaceted process that requires careful consideration of various factors. By analyzing project requirements, evaluating cable properties, considering application and environment, complying with regulations, managing voltage drop, balancing budgetary constraints, planning for future expansion, and prioritizing supplier reputation and safety, you can make informed decisions that enhance your success rate items. Proper cable selection not only ensures efficient energy transfer, but also contributes to the overall reliability, safety and longevity of electrical and electronic systems.

ANYTE Cable Co., Ltd. is a leading cable manufacturer dedicated to providing high quality, advanced cable solutions. Establish partnerships with German cable manufacturers, and adopt German advanced manufacturing technology and design concepts in products. Consultation is available at any time if necessary.

Related Products