I. Introduction

As an indispensable part of electrical engineering, cables play an important role in transmitting power and information. In recent years, the competition between multicore cables and single-core cables has attracted a lot of attention, and this paper aims to study in depth the advantages of multi-core cables over single-core cables.

a. Key role of cables in electrical engineering

Cables bear the mission of transmitting power and signals in electrical systems, and are widely used in various equipment and fields, thus becoming an indispensable part of ensuring the normal operation of the system.

b. Competition between multicore cables and single-core cables raises concerns

In recent years, the development of cable technology has triggered fierce competition between multi-core cables and single-core cables. The choice between the two has become a key issue in the field of electrical engineering, and the advantages of each will be explored in detail in this paper.

c. Purpose of Exploring the Advantages of Multi-core cables over Single-core Cables

The purpose of this paper is to deeply analyze the advantages of multicore cables over single-core cables, and through systematic research, to provide professionals in the field of electrical engineering with a comprehensive understanding, and to provide a strong basis for future cable selection.

II. Introduction to multi-core cables

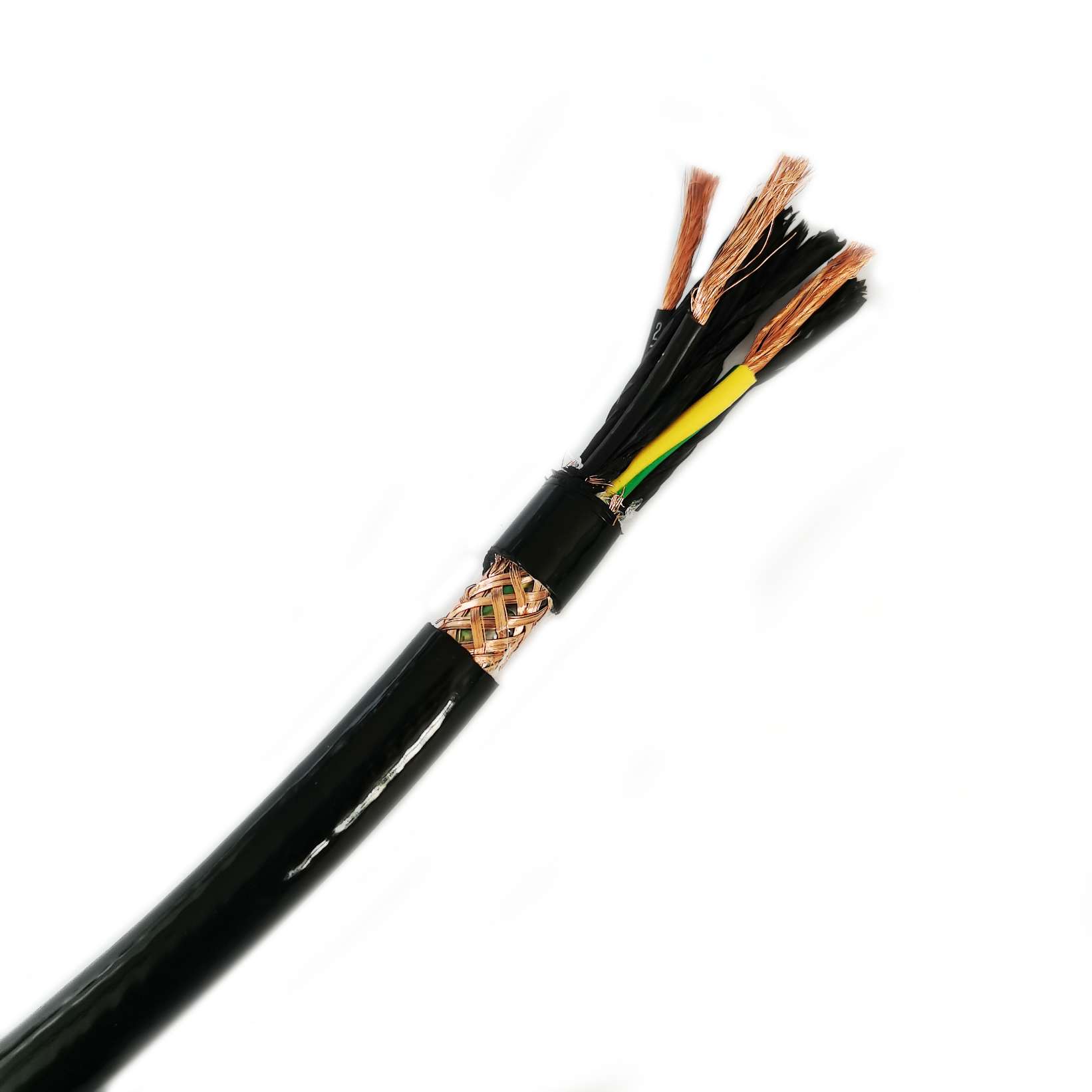

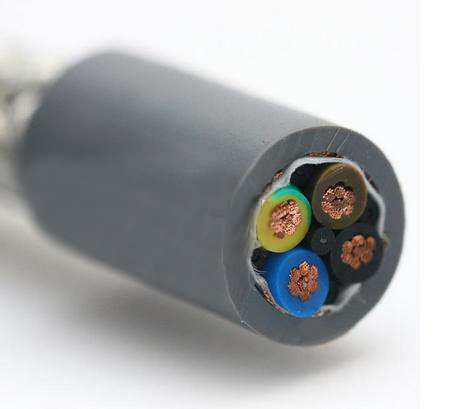

- Definition and structure of multi-core cable

Multi-core cable is a type of cable that contains multiple insulated cores within the same cable sheath, and is constructed with multiple conductors coexisting in a flexible outer sheath.

- Comparison of the basic characteristics of single-core cables

Comparatively, single-core cables consist of a single conductor, usually encased in an insulating layer. This fundamental difference in structure provides the basis for the subsequent analysis of advantages.

- Application areas of multicore cables

Multi-core cables are suitable for a wide range of scenarios due to their structural flexibility, including but not limited to industrial automation, audio and video systems, automotive applications, and telecommunications.

III. Advantage 1: Flexibility and Maneuverability

- Flexibility of Multi-core Cable Structure

Multicore cables stand out with their unique structure, and their multi-conductor design allows them to show excellent flexibility in different applications. Each conductor is housed in a common sheath, allowing the overall cable to be easily bent and adapted to a variety of complex environments.

- Superiority in Confined Spaces, Complex Paths and Frequent Movement Applications

In contrast, single-core cables, due to the limitations of their single conductor, exhibit relative limitations in applications that traverse confined spaces, are routed along complex pathways, or require frequent movement. Multicore cables exhibit greater adaptability and maneuverability in these scenarios.

- Limitations of Single-Core Cables in the Same Situations

The relatively rigid structure of single-core cables makes it difficult to flexibly adapt to narrow spaces or paths that require bending. In environments with frequent movement, single-core cables may be more susceptible to stress and damage.

IV. Advantage 2: Simplified installation and maintenance

- Overall installation process of multicore cables

Multi-core cables simplify the overall installation process by integrating multiple conductors into a single cable. This not only reduces the overall size of the cable, but also simplifies the wiring and termination procedures and improves the overall installation efficiency.

- Simplification of wiring and termination procedures

The organized structure of multicore cables makes the wiring and termination process more intuitive and simplified compared to single-core cables. This is crucial for the ease of use of electrical engineers in the field.

- Maintenance and troubleshooting advantages

When it comes to maintenance or troubleshooting, the organized structure of multi-core cables helps to identify and solve problems faster. Compared to single-core cables, multicore cables can locate the point of failure more quickly, increasing system reliability.

V. Advantage 3: Signal Integrity Enhancement

- Minimization of electromagnetic interference and inter-conductor crosstalk

The construction of multicore cables reduces the risk of electromagnetic interference (EMI) and inter-conductor crosstalk by separating different conductors in the same cable. This is especially important in scenarios requiring high signal integrity.

- Importance in data transmission, telecommunications and control systems

Signal integrity is critical in applications involving data transmission, telecommunications and control systems. Multicore cables improve overall system stability and reliability by reducing signal interference.

- Signal integrity challenges of single-core cables

Comparatively, single-core cables may be more susceptible to external electromagnetic interference due to the relative proximity of the conductors, thus reducing signal integrity.

VI. Advantage 4: Versatility Across Applications

- Adaptability of multi-core cables in various applications

Multicore cables show excellent adaptability in various applications with their diverse designs. Its multi-conductor structure makes it possible to transmit signals of different functions at the same time, meeting the multifunctional needs of cables for different applications. From power transmission to data transmission, multi-core cables are capable of performing in a wide range of industrial, commercial and domestic applications.

- Examples from industrial automation, audio/video systems and automotive applications

Industrial Automation

In industrial automation, multicore cables are commonly used to connect various sensors, actuators and control devices. Its flexibility and versatility allow it to adapt to complex automation systems, providing reliable power and signal transmission for industrial processes.

Audio and Video Systems

In audio and video systems, multicore cables are often used to transmit audio, video and control signals. The design of this single cable for multiple signals simplifies cabling structures and provides clear, high-quality audio and video transmissions.

Automotive Applications

Multi-core cables offer significant advantages in automotive applications, where the requirements are extremely stringent. It can transmit power, and control signals and data at the same time, adapting to the complex electrical systems of automobiles and providing reliable connections and communications.

- Versatility is not possible with single-core cables

In contrast, single-core cables have difficulty in meeting the need for simultaneous transmission of multiple signals because they have only one conductor. In applications where power, data and control signals need to be integrated, single-core cables may require the use of multiple cables, adding to the complexity and cost of wiring. The design of multi-core cable makes it capable of handling these complex and multi-functional applications, making it a more powerful choice for comprehensive performance.

VII. Advantage 5: Efficient use of space

- Advantages in Dense Control Panels, Cable Trays and Limited Space

Multicore cables show excellent advantages in space-constrained environments, especially in dense control panels, cable trays and limited spaces. Its design integrates multiple conductors into a single sheath to maximize and optimize the use of available space. This allows for more efficient deployment and organization of cable systems in applications such as industrial automation, data centers and telecommunication facilities, ensuring tight connections between devices.

- Contribution to a neat, organized layout

The design of multi-core cables makes it possible to achieve a neater and more organized structure when laying out cable systems. Since multiple conductors are grouped together, there is less confusion and entanglement, reducing the likelihood of cables interfering with each other. This greatly facilitates the visualization and identification of problems during maintenance and troubleshooting. Engineers are able to identify and deal with problems more easily, shortening repair time and improving system reliability.

- Limitations of single-core cables in terms of space utilization

In contrast, single-core cables have more independent and decentralized wiring because they have only one conductor. In a limited space, multiple single-core cables may need to be used to meet the needs of different functions, increasing the complexity of the system. In addition, the wiring of single-core cables may be more prone to confusion, which is not conducive to maintenance and management, especially in environments where frequent changes or upgrades are required, and such confusion may lead to unnecessary problems and delays.

VIII. Advantage 6: Cost-effective solution

- Relatively high initial investment for multicore cables

Multi-core cables may have a slightly higher initial investment relative to single-core cables, mainly due to their complex construction and multi-functional design. Manufacturing costs are relatively high due to the need to use multiple conductors with precision insulation and assembly in a single cable. However, this increase in initial investment pays off in long-term operation in the form of multiple advantages in installation, maintenance and performance.

- Demonstration of long-term cost-effectiveness

Simplifying the installation process

Multi-core cables are designed to simplify the installation process by reducing the overall wiring complexity by integrating multiple conductors into a single cable. This not only saves installation time, but also reduces labor costs, providing economic benefits to the project.

Reduced Maintenance Costs

When it comes to maintenance and troubleshooting, the organized structure of multicore cables makes locating and resolving problems quicker and more efficient. This reduces the time and labor required for maintenance and takes the pressure off maintenance costs.

Adapting to versatility reduces procurement costs

The versatility of multi-core cables means that one type of cable can be used in a given project without the need to procure multiple single-core cables for different functions. This simplifies inventory management and the procurement process, reducing inventory costs.

- Status of multicore cables as a strategic investment

Improved system reliability

The structural design and superior performance of multicore cables increase the reliability of the entire electrical system. This is critical for systems that require stable and reliable power and data transmission, such as industrial automation and communication systems.

Meeting future technological demands

Multi-core cables not only fulfill current electrical requirements, but also support future technological innovations. Their flexibility and versatility allow them to adapt to evolving technological requirements, making system upgrades and expansions feasible.

Maintaining long-term competitive advantage

Despite the high initial investment, the long-term cost-effectiveness of multi-core cables and their adaptability to future technological trends make them a strategic investment. In an ever-changing market, electrical systems with a long-term competitive advantage will be more attractive.

VIII. Advantage VI: Cost-effective solution

- Relatively high initial investment in multicore cables

Multi-core cables may have a slightly higher initial investment compared to single-core cables, mainly due to their complex construction and multifunctional design. Manufacturing costs are relatively high due to the need to use multiple conductors with precision insulation and assembly in a single cable. However, this increase in initial investment pays off in long-term operation in the form of multiple advantages in installation, maintenance and performance.

- Demonstration of long-term cost-effectiveness

Simplifying the installation process

Multi-core cables are designed to simplify the installation process by reducing the overall wiring complexity by integrating multiple conductors into a single cable. This not only saves installation time, but also reduces labor costs, providing economic benefits to the project.

Reduced Maintenance Costs

When it comes to maintenance and troubleshooting, the organized structure of multicore cables makes locating and resolving problems quicker and more efficient. This reduces the time and labor required for maintenance and takes the pressure off maintenance costs.

Adapting to versatility reduces procurement costs

The versatility of multi-core cables means that one type of cable can be used in a given project without the need to procure multiple single-core cables for different functions. This simplifies inventory management and the procurement process, reducing inventory costs.

- Status of multi-core cables as a strategic investment

Improved system reliability

The structural design and superior performance of multicore cables increase the reliability of the entire electrical system. This is critical for systems that require stable and reliable power and data transmission, such as industrial automation and communication systems.

Meeting future technological demands

Multi-core cables not only fulfill current electrical requirements, but also support future technological innovations. Their flexibility and versatility allow them to adapt to evolving technological requirements, making system upgrades and expansions feasible.

Maintaining long-term competitive advantage

Despite the high initial investment, the long-term cost-effectiveness of multi-core cables and their adaptability to future technological trends make them a strategic investment. In a changing market, electrical systems with a long-term competitive advantage will be more attractive.

XII. Conclusions

- Combined advantages of multicore cables

Multi-core cables demonstrate superior advantages in terms of flexibility, simplified installation and maintenance, improved signal integrity, versatility across applications, efficient use of space, and cost-effectiveness. These advantages make multi-core cables one of the preferred solutions in electrical engineering. Their flexible design and diverse range of applications provide reliable connections and high performance for a wide variety of electrical and electronic systems.

- Perspectives in electrical and electronic systems

Multi-core cables have a wide range of prospects in electrical and electronic systems. From industrial automation to audio/video systems, from automotive electrical systems to communications, multicore cables are able to fulfill the needs of different systems for power transmission and data transmission. Their versatility and adaptability make them an important part of the drive for technological innovation in different fields.

- Future status of multi-core cables

As technology continues to evolve, multi-core cables will continue to play a key role in electrical engineering. In the future, we can expect to see even more advanced and lightweight multi-core cables that are adapted to the changing needs of the market. Intelligence, sustainability and higher performance will be key trends in the future development of multi-core cables, contributing to a more efficient and reliable electrical infrastructure.

By taking a comprehensive look at the combined advantages of multicore cables, their prospects in electrical and electronic systems and future trends, we can conclude that multi-core cables will continue to play an important role in electrical engineering, providing reliable connectivity solutions for a wide range of applications and driving continuous innovation in electrical technology.