Introduce

In the world of complex cable installations, a critical factor that is often overlooked is proper grounding and installation. While selecting the correct multicore shield cable is critical, it is equally important to ensure the cable is properly installed and grounded. This article provides an in-depth look at installation and grounding techniques for multiconductor shielded cables, illustrating best practices to ensure optimum performance and safety in a variety of applications.

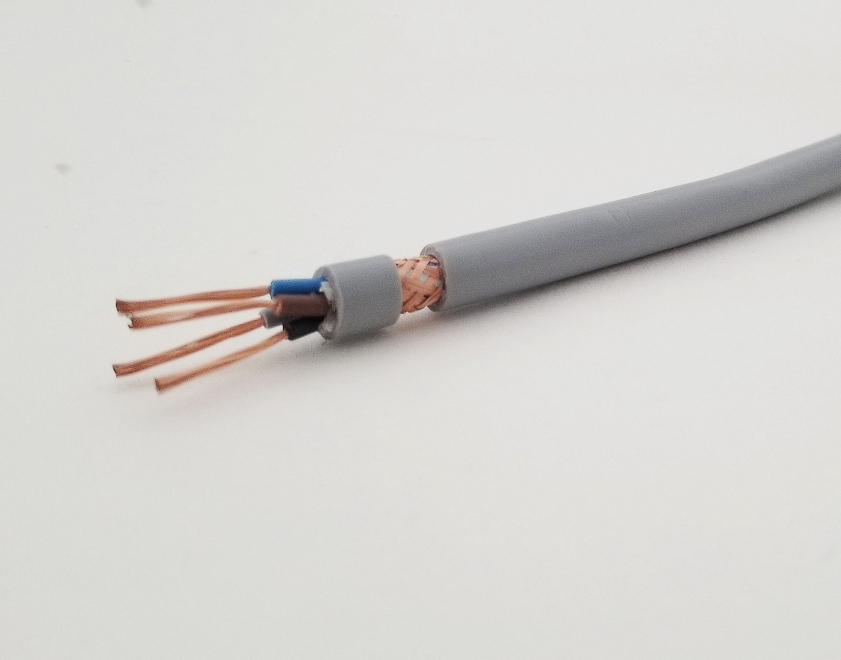

Learn about multicore shielded cables

High-efficiency multicore shield cable is a versatile cabling solution used in a wide range of industries from industrial automation to telecommunications. These cables consist of multiple insulating cores surrounded by a metal shield designed to protect the signal from electromagnetic interference (EMI) and radio frequency interference (RFI). This design ensures consistent signal integrity, making it ideal for environments where interference is harmful.

Preparations before installation

Thorough pre-installation preparation is key before embarking on the installation journey. Consider the specific requirements of the project and the environmental conditions the cable will be exposed to. Evaluate factors such as conductor size, insulation material, shielding type and intended use of the cable. By tailoring your cable selection to these parameters, you can set the stage for a successful installation.

installation guide

Installing a multicore shield cable requires careful planning and execution. Start by carefully planning the cable routing, taking care to avoid potential sources of interference. Maintaining the recommended bend radii prevents unnecessary mechanical stress on the cables and thus ensures their longevity. Sharp bends, excessive twisting, and excessive tension should be avoided during installation as they can compromise signal transmission and overall cable integrity. Secure cables with proper fasteners to prevent sag and strain from negatively impacting performance.

Proper Shield Termination

Proper termination of the cable shield is a critical step in ensuring optimum performance. This shield is the first line of defense against external interference, so it must be connected to a reliable ground reference point. Selecting high-quality connectors and grounding hardware is critical to maintaining effective shielding. Improper shield termination can cause signal attenuation and increase susceptibility to interference.

grounding technology

Grounding plays a key role in the overall success of multiconductor shielded cable installations. The cable shield must be effectively grounded to provide a clear path for the dissipation of unwanted electromagnetic energy. Two common grounding techniques are single-point grounding and multi-point grounding. A single-point ground connects all shields to a single ground reference, while a multi-point ground distributes the connection to multiple ground points. Careful consideration of the application’s requirements and potential sources of interference will guide the choice of grounding technique.

Electrostatic Discharge (ESD) Protection

During installation, the cables must be protected from electrostatic discharge (ESD). ESD can cause irreparable damage to sensitive components within the cable. Handlers should be properly grounded and should follow procedures such as wearing a grounded wrist strap and using an ESD-safe work surface. By taking proactive steps to prevent ESD, you can ensure the longevity and performance of your cables.

Testing and Validation

The installation process is ultimately thoroughly tested and validated. Testing cables for continuity, insulation resistance and shield integrity is critical before concluding installation. Professional testing equipment can help identify potential problems that may arise during installation. Testing to verify proper installation and grounding minimizes the risk of future signal interruptions and performance degradation.

Comply with standards and regulations

The installation and grounding of high-quality multicore shield cables must comply with relevant industry standards and regulations. Adherence to these guidelines not only ensures cable safety, but also interoperability and reliability. Compliance is the cornerstone of a successful installation and should not be overlooked.

Maintenance and Monitoring

Proper installation and grounding are not static processes; they require constant attention. Regular inspection and maintenance of installed cables will help extend their life and improve their performance. Monitoring cable performance over time can reveal subtle changes that may affect signal quality, allowing timely intervention and maintenance.

FAQ Troubleshooting

Despite careful planning, problems can arise during installation. Identifying common problems such as improper shield termination, insufficient grounding, or mechanical stress on the cable can help to effectively troubleshoot and resolve these challenges. By addressing these issues in a timely manner, you can safeguard the performance of your cables and prevent potential downtime.

In conclusion

In the field of cable installation, proper grounding and installation techniques cannot be ignored. Premium multicore shield cables have intricate designs and shielding features that require careful handling to ensure optimum performance and safety. From pre-installation preparations to post-installation testing and maintenance, every step plays a vital role in ensuring reliable signal transmission, minimizing interference, and enhancing security for a variety of applications. By mastering the art of installation and grounding, you can pave the way for success in projects requiring high-performance cable solutions.

ANYTE Cable Co., Ltd. is a leading cable manufacturer dedicated to providing high quality, advanced cable solutions. Establish partnerships with German cable manufacturers, and adopt German advanced manufacturing technology and design concepts in products. Consultation is available at any time if necessary.

Related Products