The NHXH cable, a variant in the family of halogen-free, flame-retardant cables, is designed to ensure safety in environments where the risk of fire and its subsequent hazards (like toxic emissions) need to be minimized. Such environments include residential buildings, hospitals, schools, and industrial areas where the integrity of electrical installations is critical for safety and operational reliability. This article delves into the specifications, variations, and suitability of these cables for specific installations, shedding light on their importance in modern electrical engineering and construction projects.

Understanding NHXH Cables

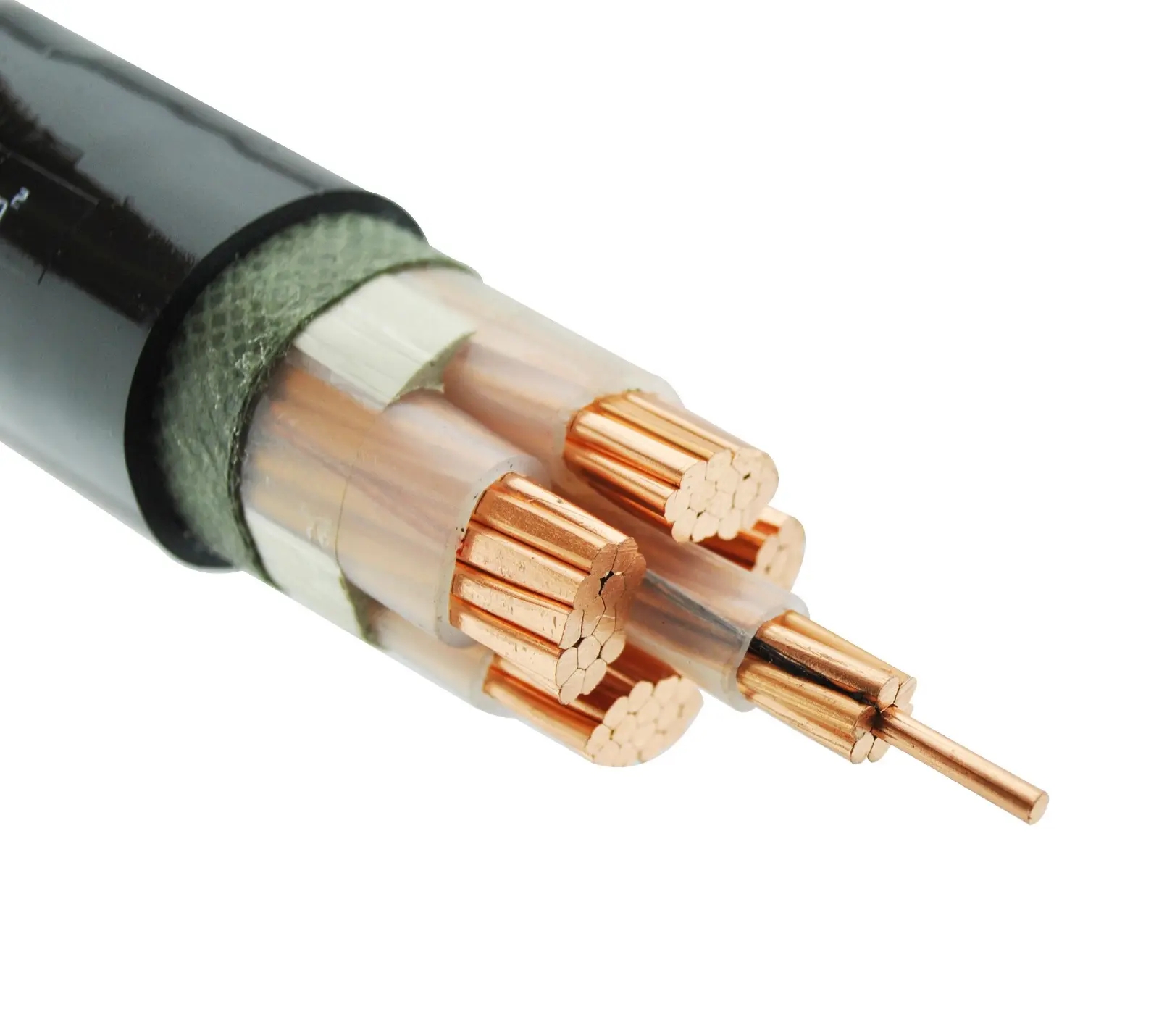

They are constructed using halogen-free materials. These materials do not emit toxic gases or smoke when exposed to fire, significantly enhancing the safety of the installations and making evacuation in case of fire easier and safer. The “H” in NHXH stands for halogen-free, and the “X” indicates that the insulation is made from cross-linked polyethylene (XLPE), which provides excellent electrical properties, thermal resistance, and mechanical durability.

Specifications of NHXH Cables

They are subject to rigorous standards that define their construction, performance, and testing criteria. These specifications ensure that the cables meet the necessary safety, operational, and environmental requirements. Key specifications include:

- Voltage Rating: They are typically rated for 0.6/1 kV, suitable for medium voltage applications.

- Conductor Material: Copper is commonly used for its excellent conductivity and durability.

- Insulation: Cross-linked polyethylene (XLPE) insulation is used for its superior electrical insulation properties, resistance to heat, and mechanical strength.

- Outer Sheath: The outer sheath is made from halogen-free compounds, providing flame retardancy and low smoke emission.

- Flame Retardant: These cables comply with flame retardant standards such as IEC 60332-1, ensuring that the cable does not propagate fire.

- Halogen-Free: The cables are manufactured without halogens, preventing the emission of toxic gases during combustion.

Variations of NHXH Cables

The variations in these cables primarily involve differences in conductor size, number of conductors, and additional protective features, which affect their application and installation suitability. Some common variations include:

- Single-Core vs. Multi-Core: These cables can be single-core or multi-core, depending on the application’s power requirements and installation conditions.

- Armoured vs. Unarmoured: For installations where mechanical protection is necessary, such as in direct burial or in areas prone to physical damage, armoured They are available. Unarmoured versions are suitable for protected installations, such as inside conduits or cable trays.

- Shielding: Shielded cables include a layer of metallic tape or wire braid to protect against electromagnetic interference (EMI), making them suitable for environments with high levels of electrical noise.

Suitability for Specific Installations

The choice of NHXH cable for a particular installation depends on several factors, including the environmental conditions, installation method, and electrical requirements of the application. Some considerations include:

- Indoor vs. Outdoor Installation: While all cables are suitable for indoor use, outdoor installations may require cables with UV-resistant sheaths or additional mechanical protection.

- Fire Safety Requirements: In areas with stringent fire safety regulations, they are preferred due to their flame-retardant and low-smoke properties.

- Electromagnetic Compatibility (EMC): In installations sensitive to electromagnetic interference, such as data centers or industrial control rooms, shielded cables may be necessary to ensure signal integrity and system reliability.

- Mechanical Protection: In environments where cables are exposed to potential mechanical damage, armoured cables offer the necessary protection to maintain cable integrity.

With advancements in materials science and regulatory standards focusing increasingly on safety and environmental impact, they have become a cornerstone in designing electrical installations that prioritize both. The detailed examination of NHXH cables’ specifications, variations, and application suitability is not merely academic but serves a practical purpose in guiding the selection of the appropriate cable type for specific installation environments. This decision-making process is critical in ensuring the long-term reliability and safety of electrical installations, especially in sectors where the risk of fire can have catastrophic consequences.

Evolving Standards and Future Directions

The standards governing NHXH cables, such as those set by the International Electrotechnical Commission (IEC), are subject to continuous review and enhancement. These evolving standards reflect the latest scientific findings on material safety, fire prevention, and environmental protection. As global awareness of these issues increases, the criteria for it are becoming more stringent, pushing manufacturers to innovate in terms of materials, manufacturing processes, and cable design.

Environmental Considerations

Beyond safety, the environmental impact of NHXH cables is an important consideration. The halogen-free nature of these cables means that they are less harmful to the environment both during use and at the end of their lifecycle. As sustainability becomes a central consideration in construction and engineering projects, the environmental benefits of it make it an increasingly attractive option.

Challenges and Opportunities

Despite their advantages, NHXH cables face challenges in terms of cost and technical requirements. The materials and manufacturing processes involved in producing halogen-free, flame-retardant cables can be more expensive than those for standard cables. Furthermore, the installation of these cables may require specialized knowledge and techniques to ensure their performance and safety benefits are fully realized.

However, these challenges also present opportunities for innovation. For instance, research into new materials and technologies may lead to the development of more cost-effective and environmentally friendly alternatives to current cables. Additionally, advancements in cable design and manufacturing could further enhance the performance and reduce the costs of these cables.

The Role of NHXH Cables in Modern Electrical Installations

They play an essential role in modern electrical installations, where the emphasis on safety, environmental impact, and reliability is greater than ever. Their specifications and variations cater to a wide range of applications, ensuring that installations meet the highest standards for safety and performance. As the industry evolves, so too will the technologies and standards surrounding its cables, ensuring that they continue to meet the needs of a changing world. The informed selection of NHXH cables, based on a comprehensive understanding of their characteristics and suitability for specific installations, is fundamental to the success of electrical projects that prioritize safety and sustainability.

Conclusion

NHXH cables represent a critical component in modern electrical installations, particularly in environments where safety, reliability, and environmental considerations are paramount. Understanding the specifications, variations, and suitability of these cables for specific installations ensures that engineers and contractors can make informed choices, optimizing the safety and efficiency of electrical systems. As technology and standards evolve, their capabilities and applications of are likely to expand, further enhancing their role in safe and efficient electrical infrastructure.