In today’s technology-driven world, cables play a key role in connecting and powering a wide variety of devices and systems. Among the many cable materials available, polyurethane (commonly known as PUR) is recognized for its excellent properties and performance. In this article, we delve into the unique advantages of using PUR cable over other types of cables.

Introduction

Before we dive into the benefits of PUR cable, it is crucial to understand the importance of wiring for products such as RV-K in modern applications. Cables are the lifeblood of countless industries including telecommunications, manufacturing, automation and more. The choice of cable material can significantly affect performance, durability and cost-effectiveness.

Flexibility and durability

A. Excellent flexibility of PUR cables

One of the outstanding features of PUR cables is their exceptional flexibility. This characteristic stems from the cable’s polyurethane sheath, which is known for its flexibility.

B. Ease of installation and wiring

The flexibility of PUR cables makes them very easy to install and route. Whether you are dealing with complex cable layouts in a data center or need to maneuver cables around tight corners in industrial machinery, PUR cables provide a solution to simplify the process.

C. Bending fatigue resistance

Another key aspect is its resistance to bending fatigue. They can withstand repeated flexing without compromising their integrity, making them suitable for applications where the cable moves frequently.

Resistant to harsh environments

A. Thriving under challenging conditions

Excellent performance in challenging environments, including those with extreme temperatures, exposure to chemicals and abrasive conditions.

B. Comparison with other cable materials

Compared to traditional cable materials such as PVC or rubber, safety PUR cables maintain their performance and structural integrity even when exposed to harsh chemicals or extreme temperatures. This resistance ensures their reliability in demanding applications.

Electrical characteristics

A. Excellent electrical characteristics

In addition to physical properties, it also has excellent electrical properties. This includes insulation properties and signal transmission capabilities.

B. Performance comparison

PUR cables generally exhibit superior electrical properties compared to other cable materials. This enables more efficient data transfer and reduces signal interference.

Wear resistance and mechanical resistance

A. To withstand wear and tear

Wear resistance is a critical factor in many applications. PUR cables are designed to withstand abrasion and mechanical stress, which is critical in industries where cables are constantly moving and wearing out.

B. Industrial machinery and robots

In environments where cables are constantly in motion, such as industrial machinery and robots, the sturdiness of PUR cables becomes a valuable asset. They maintain integrity even in the harshest industrial environments.

Design and customization flexibility

A. Custom Solutions for Unique Applications

PUR cables offer a high degree of flexibility in terms of design and customization. This makes them ideal for specialized applications requiring specific cable configurations.

B. Dimensions, Shielding and Connector Options

Whether you need a uniquely sized cable, special shielding for EMI protection, or a specific connector for your application, PUR cables can be customized to meet your exact requirements.

Long service life and cost-effective

A. Long-term investment

The durability and resistance of PUR cables help to extend their life. While their initial cost may be slightly higher, their longevity means cost savings in the long run.

B. Cost-benefit analysis

Cost-benefit analyzes often favor PUR cables due to their longer life, lower maintenance requirements and the ability to minimize downtime in critical applications.

Comparison with other cable types

A. Introduction of other cable materials

In order to fully understand the advantages of PUR cables, it is necessary to introduce and briefly describe other common cable materials, such as PVC and rubber.

B. Highlight advantages

By comparing the characteristics and performance of PUR cables to these alternatives, it becomes clear why PUR is the better choice in many cases.

Practical application

A. Industries and Applications

Let’s take a closer look at some real world industries and applications where PUR cables have proven to be the first choice.

B. Case studies and success stories

Through case studies and success stories, we’ll learn how PUR cables can positively impact business and industry, improving performance and reliability.

Conclusion

A. Summary of the advantages of PUR cables

In summary, PUR cables have a number of unique advantages that set them apart from other cable materials. Their flexibility, durability, resistance to harsh environments, excellent electrical performance and customization options make them the first choice for many industries.

B. Encourage consideration

As the industry continues to evolve, the choice of cabling solution becomes more and more important. We hope this article will shed light on the significant advantages of PUR cables and encourage businesses and industries to consider these cables when selecting cabling solutions. Whether for data centers, industrial machinery, robotics or any other application, PUR cables demonstrate how innovations in cable technology drive progress and reliability in the modern world.

Related Products

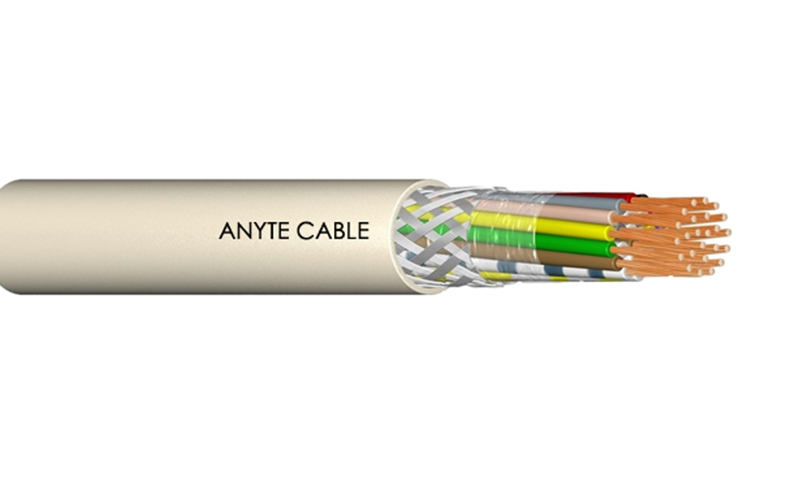

PUR multi core cable