Introduce

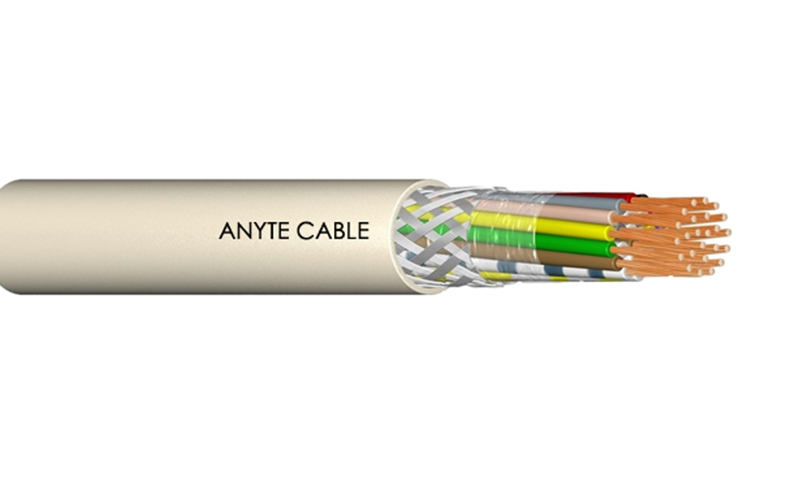

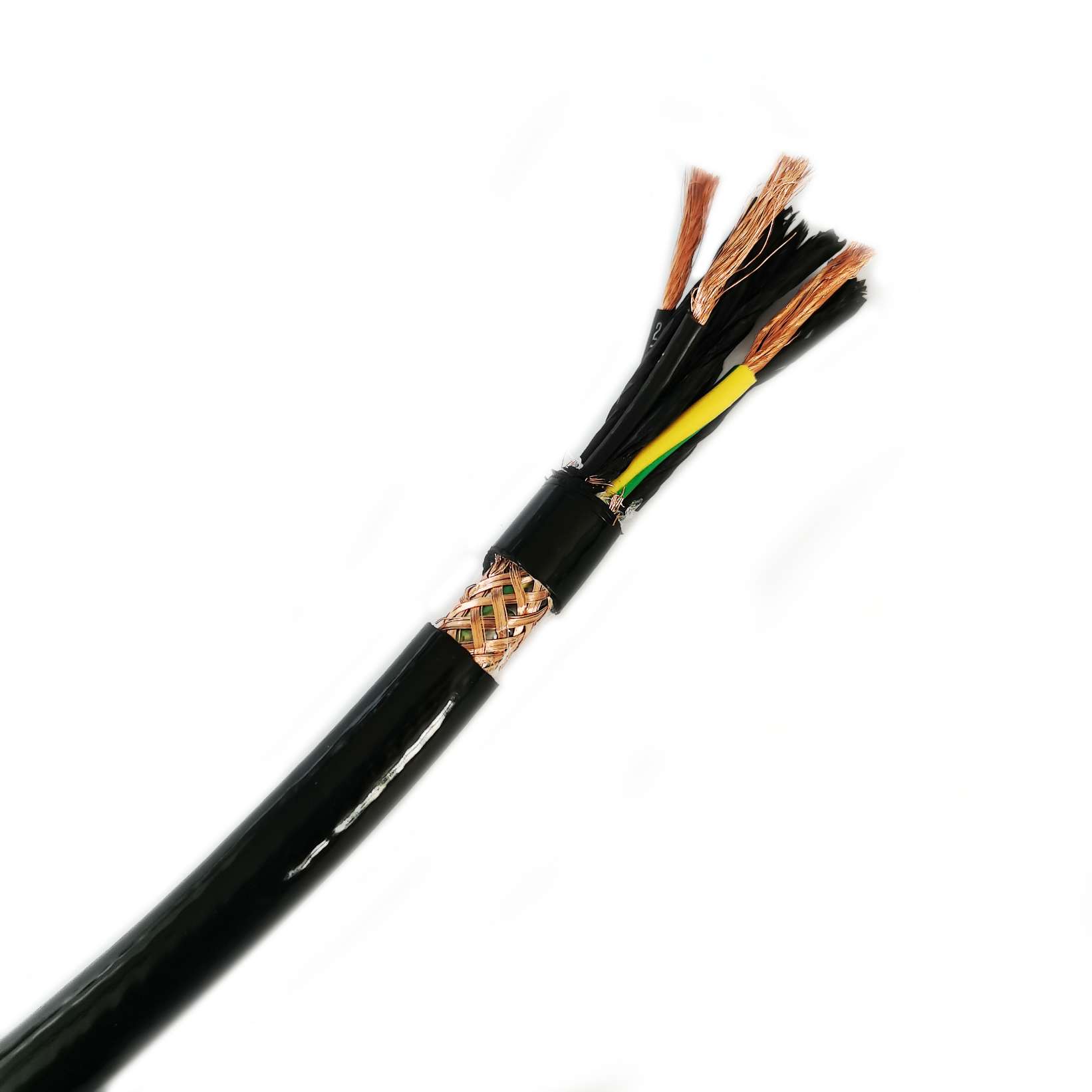

High-quality PUR cable uses multiple thin wires to increase its flexibility and durability. The thin wires, usually made of copper or other conductive material, are bundled together to form a cable. The use of multiple fine wires allows for a more flexible and durable cable that can withstand the demands of industrial and commercial applications. Using PUR as the outer sheath also provides additional protection from abrasion and other environmental elements.

In addition to flexibility and durability, high-quality PUR cable also has other advantages, such as high oil and chemical resistance, good electrical insulation properties and high temperature resistance. These characteristics make them suitable for a wide range of industrial and commercial applications, including robotics, automation, and control systems.

Advantages of PUR cable

One of the main advantages of PUR multi core cable is its flexibility. Using multiple thin wires allows the cable to bend and bend easily, making it easier to pass through tight spaces and around obstacles. This flexibility also makes the cable less susceptible to damage from vibration and movement, which is especially important in applications where the cable moves or vibrates a lot.

Another important advantage of PUR multicore cables is their resistance to oils and chemicals. The PUR outer sheath provides a barrier that prevents liquids and chemicals from penetrating the cable and helps protect the wires inside. This is especially important in industrial and commercial applications where cables may be exposed to oils, solvents and other chemicals.

In terms of electrical insulation properties, multi-core cables are known for their good insulation properties. This is due to the use of high-quality insulation and the tight construction of the cables, which help prevent electrical leakage and reduce the risk of electrical fires or other hazards.

Finally, high-quality PUR cable is also known for its high temperature resistance. The PUR outer sheath can withstand temperatures up to 150°C, which makes it suitable for high temperature environments such as foundries, ovens and other industrial applications.

In summary, multicore cables are a popular choice for industrial and commercial applications due to their flexibility, durability, oil and chemical resistance, good electrical insulation properties, and high temperature resistance. Using multiple fine wires in the cable construction helps to increase the flexibility and durability of the cable, making it a versatile and reliable choice for a wide range of applications.

Another advantage is that they provide a high level of protection against wear. The PUR outer sheath is a tough and durable material that resists abrasion and helps extend the life of the cable. This is especially important in applications where cables often move or rub, such as robotics or conveyor systems.

Its cables are capable of being used in harsh environments. Materials used in construction can withstand extreme temperatures, humidity, and even exposure to ultraviolet light. This makes them suitable for outdoor or exposed applications such as industrial sites or construction sites.

Selection and application of high-quality PUR cable

PUR multicore cables are also easy to install and maintain. They are lightweight and easy to handle, which makes them easier to work with than other types of cables. Using multiple thin wires also makes it easy to identify individual wires in the cable, making troubleshooting and repairs easier if necessary.

Cables are also available in various sizes and configurations to meet the specific needs of different applications. They can be customized to meet specific requirements in terms of core count, wire gauge and overall length. This makes it a versatile choice along with YY cable for a wide range of industrial and commercial applications.

All in all, PUR multicore cables are a reliable and versatile choice for industrial and commercial applications due to their flexibility, durability, oil and chemical resistance, good electrical insulation properties, high temperature resistance, abrasion resistance and suitability for harsh environments. They are also easy to install and maintain, making them ideal for a variety of applications.

There are several factors to consider when selecting a multiconductor cable for a particular application. One of the most important factors is wire gauge. Wire gauge refers to the thickness of the individual wires within a cable, measured in American Wire Gauge (AWG). The higher the AWG number, the thinner the wire. In general, thinner wires are more flexible, but they also have a lower current carrying capacity. Therefore, it is very important to select a wire gauge that is suitable for the current and voltage requirements of the application.

Another important factor to consider is the number of cores. PUR multi-core cables are available in a variety of core counts, from 2 cores to 64 cores or more. The number of cores will depend on the specific requirements of the application. Typically, applications requiring more conductors or a higher level of control require more cores.

Insulation material is also a very important consideration. The insulating material is used to protect the wires from leakage and improve the overall electrical insulation performance of the cable. The most common insulating materials are PVC and silicone, which are known for their good insulating properties, flexibility, and high temperature resistance.

Finally, the length of the cable is an important factor to consider. The length of the cable will depend on the specific requirements of the application. It is important to select the correct length of cable for the application to ensure that it can be easily routed and connected to the necessary equipment.

In summary, when selecting a PUR cable for an application, it is important to consider factors such as wire gauge, number of cores, insulation material, and length. These factors will help ensure that the cable is suitable for the specific requirements of the application and will provide reliable and efficient performance over time.

Anyte Cable not only develops and manufactures standard high-quality cables, but also provides excellent solutions according to your needs and product applications. Welcome your inquiry at any time.

Related Products

PUR multi core cable