The Ultimate Guide to Safe PUR Multi Core Cable: A Professional Overview

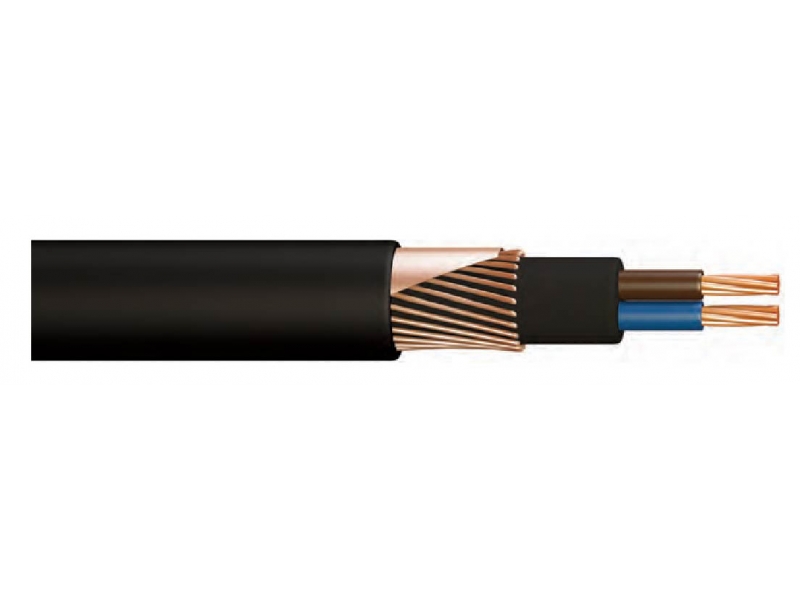

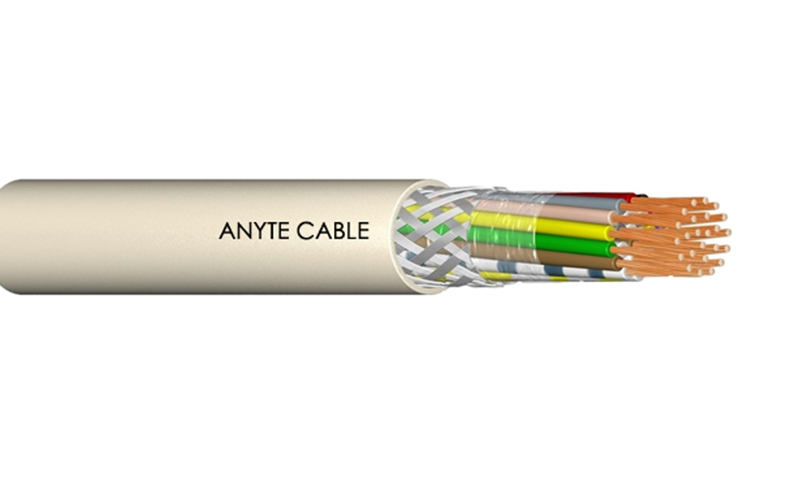

If you’re in need of a reliable and safe cable solution, you may want to consider PUR multi core cables. PUR, or polyurethane, is a thermoplastic material that is highly resistant to abrasion, chemicals, and UV radiation. Multi core cables, on the other hand, consist of multiple insulated conductors within a single cable jacket, making them ideal for use in complex electronic systems.

In this ultimate guide, we’ll provide you with a professional overview of safe PUR multi core cables. We’ll cover everything from their benefits to their applications, as well as important considerations when selecting and installing them.

What are PUR Multi Core Cables?

PUR multi core cables are cables that consist of multiple conductors within a single cable jacket, all made from polyurethane material. The polyurethane material provides the cable with excellent durability, making it resistant to harsh environmental conditions such as extreme temperatures, moisture, chemicals, and abrasion.

Benefits of PUR Multi Core Cables

There are many benefits to using PUR multi core cables from China. Some of the most significant benefits include:

-

Durability: PUR multi core cables are designed to withstand harsh environmental conditions, making them ideal for use in applications where reliability and durability are critical.

-

Flexibility: PUR multi core cables are highly flexible, making them easy to install in tight spaces or around corners.

-

Chemical Resistance: PUR multi core cables are highly resistant to chemicals, making them ideal for use in applications where exposure to harsh chemicals is expected.

-

Temperature Resistance: PUR multi core cables can withstand a wide range of temperatures, from -40°C to +90°C.

Applications of PUR Multi Core Cables

PUR multi core cables from China are used in a variety of applications across various industries. Some common applications include:

-

Robotics and Automation: PUR multi core cables are used in robotics and automation systems because of their flexibility and durability.

-

Industrial Equipment: PUR multi core cables are used in industrial equipment, including machine tools, conveyors, and pumps.

-

Medical Equipment: PUR multi core cables are used in medical equipment, including diagnostic machines, surgical tools, and imaging equipment.

-

Transportation: PUR multi core cables are used in transportation applications, including railway signaling, traffic control systems, and aircraft.

Selecting and Installing PUR Multi Core Cables

When selecting and installing PUR multi core cables, there are a few important considerations to keep in mind. These include:

-

Cable Design: It’s essential to select a cable design that matches the requirements of the application. This includes selecting the right number of conductors, conductor size, and cable jacket material.

-

Environmental Conditions: The environmental conditions of the application should be considered when selecting PUR multi core cables. Factors such as temperature range, exposure to chemicals, and exposure to UV radiation should all be taken into account.

-

Installation: PUR multi core cables should be installed according to the manufacturer’s instructions to ensure optimal performance and safety. This includes selecting the right connectors, routing the cables correctly, and ensuring proper grounding.

-

Maintenance: Regular maintenance and inspections of PUR multi core cables can help detect and prevent potential issues before they become critical.

Conclusion

PUR multi core cables are an excellent solution for applications that require reliable and durable cable solutions. Their flexibility, chemical resistance, and temperature resistance make them ideal for use in a variety of industries, including robotics and automation, industrial equipment, medical equipment, and transportation.

When selecting and installing PUR multi core cables, it’s essential to consider factors such as cable design, environmental conditions, installation, and maintenance to ensure optimal performance and safety. By following these guidelines, you can ensure that your PUR multi core cables provide reliable and long-lasting performance.

Anyte Cable not only develops and manufactures standard high-quality cables, but also provides excellent solutions according to your needs and product applications. Welcome your inquiry at any time.

Related Products