Introducir

popular cable ul tpu, also known as UL rated thermoplastic polyurethane cable, is a versatile and reliable cabling solution with several key features and benefits. Understanding these characteristics is critical when selecting the proper cable for a specific application.

Main characteristics of UL TPU cable

UL TPU cables are unique due to their superior performance and durability.

A. Thermoplastic Polyurethane (TPU) Insulation

Excellent flexibility and durability ul tpu cable is known for its excellent flexibility, which can be easily installed in small spaces and complex configurations. Its flexible nature allows for smooth routing and reduces the risk of damage during installation or moving. Additionally, the TPU insulation offers exceptional durability, making it resistant to cracking, scuffing, and wear and tear over time.

Abrasion and Chemical Resistance One of the key benefits of UL TPU cables is their resistance to abrasion and chemicals. This makes it suitable for applications exposed to harsh environments such as mechanical stress, oils, solvents and chemicals. TPU insulation provides a protective barrier to ensure long-term reliability and performance.

Wide temperature range tolerance ul tpu cable is designed to withstand a wide range of temperatures. It operates effectively in both high and low temperature environments, ensuring consistent performance without degradation or loss of electrical performance. This temperature tolerance makes it suitable for a variety of indoor and outdoor applications.

B. UL certification

Safety Standards and Regulations Compliant Cables are rigorously tested and evaluated to meet safety requirements as set forth by Underwriters Laboratories (UL). This certification ensures that cables are manufactured to the highest industry standards, guaranteeing the safety and reliability of their application.

Quality and Reliability Assurance UL certification provides users and installers with peace of mind as it verifies the quality and performance of the cable. It shows that the cable has been tested and meets specific standards, assuring the end user that they are investing in a reliable and high-quality product.

Suitable for various applications The UL certification of popular ul tpu cable makes it suitable for a wide range of applications in various industries. Whether used in industrial automation, automotive systems or medical devices, this certification ensures compliance with safety standards and regulations.

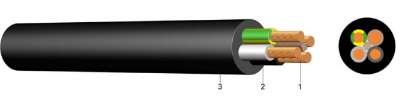

C. Stranded Copper Conductor

Efficient power transmission The cable blindado multinúcleo uses stranded copper conductors for excellent electrical conductivity and high-efficiency power transmission. The stranded design enhances flexibility and allows for easier installation, making it suitable for applications requiring frequent movement or flexibility.

Flexibility and Ease of Installation Stranded copper conductors contribute to the flexibility of the cable, allowing it to be easily installed in a variety of configurations. The flexibility of the conductors allows for bending and routing without compromising the performance of the cable. It simplifies the installation process and reduces the risk of cable damage or breakage during installation or maintenance.

Enhanced Conductivity and Signal Integrity The use of stranded copper conductors in the cable ensures optimum conductivity, minimizing resistance and voltage drop. This results in efficient power transfer and improved signal integrity, making it suitable for applications where reliable and high-quality signals are critical.

Advantages of UL TPU Cables

UL TPU cables offer several distinct advantages that make them the first choice for many industries and sectors.

A. Flexibility and Durability

Easy installation in small spaces Durability ul tpu cable has excellent flexibility and can be easily installed in small spaces, suitable for applications with limited space or complex wiring. Its bending and maneuvering capabilities ensure a hassle-free installation process, saving time and effort.

Bending and twisting resistant Designed to withstand bending and twisting without compromising its electrical performance. This elasticity ensures that the cable can adapt to various installation requirements without compromising its performance or durability.

Long Life in Harsh Environments The durability of the UL TPU cable ensures a long life even in harsh environments. Its abrasion, chemical and abrasion resistance allows it to withstand harsh conditions, reducing the need for frequent replacement and minimizing downtime.

B. Superior performance

Reliable power transmission and signal quality Provides reliable power transmission to ensure that power reaches its destination with minimal loss. This results in efficient and consistent performance of electrical systems and equipment. Additionally, the cable’s excellent signal integrity makes it suitable for applications requiring high-quality data transmission.

Low Resistance and Voltage Drop The cable’s low resistance helps reduce voltage drop, ensuring that the intended voltage reaches connected equipment without significant loss. This is especially important in applications where voltage stability is critical to maintaining peak performance.

Anti-Interference and Noise Protection Designed to effectively shield against Electromagnetic Interference (EMI) and Radio Frequency Interference (RFI). This shielding prevents external noise and interference, ensuring reliable and uninterrupted data transmission.

C. Resistant to harsh environments

Excellent Oil, Chemical and Solvent Resistance UL TPU cables have excellent resistance to oil, chemicals and solvents. This capability makes it suitable for applications in industries such as manufacturing, automotive, and oil and gas, where exposure to hazardous substances is common. The resistance of the cable ensures long-term performance and minimizes the risk of damage or failure.

UV and weather resistant UL TPU cables are designed to withstand outdoor environments and exposure to UV radiation. It is resistant to weather conditions such as sunlight, rain, and extreme temperatures, ensuring reliable performance in both indoor and outdoor applications.

Suitable for indoor and outdoor applications UL TPU cables are able to withstand a variety of environmental conditions, making them suitable for indoor and outdoor applications. Whether used in industrial environments, outdoor lighting systems, or installed underground, the cable’s resistance to harsh environments ensures reliable operation.

D. Enhanced security

UL certification ensures compliance with safety standards UL certification for UL TPU cables guarantees compliance with strict safety standards and regulations. This certification provides peace of mind for users and installers that the cable has been thoroughly tested and meets the required safety standards.

Flame Retardant Features Designed with flame retardant materials to reduce the risk of fire spreading in the event of a fire. This feature enhances safety in applications where fire resistance is critical, such as building wiring or electrical installations in public places.

Protection Against Electrical Hazards Designed to provide protection against electrical hazards, including short circuits and electric shock. The construction of the cable ensures that it can withstand current stress and minimize the risk of accidents, thus ensuring the safety of users and equipment.

E. Application Versatility

Wide Range of Industries and Sectors UL TPU cables are used in a wide range of industries including manufacturing, automotive, robotics, medical and renewable energy. Its versatility makes it suitable for a wide variety of electrical installations and systems.

Compatible with various electrical systems and equipment Compatible with various electrical systems and equipment. Whether used in power distribution systems, control panels or machinery wiring, the cable’s compatibility ensures seamless integration and reliable operation.

Suitable for both stationary and mobile applications The flexibility and durability of UL TPU cables make them suitable for both stationary and mobile applications. Whether used for fixed installations or for mobile machinery or equipment, the performance of the cables is consistent and reliable.

Aplicación práctica

UL TPU cables are widely used in various industries and fields because of their excellent characteristics and advantages.

A. Industrial automation and robotics multicore shield cable is widely used in industrial automation and robotics applications. Its flexibility, durability, and resistance to abrasion and chemicals make it suitable for robotic arm wiring, control systems, and mechanical interconnects.

B. Renewable Energy Systems Renewable energy systems, such as solar and wind installations, require reliable and durable wiring solutions. Resistance to UV radiation, weather conditions and chemicals makes them ideal for connecting to solar panels, inverters and wind turbines.

C. Medical Devices Widely used in medical devices where flexibility, durability and safety are critical. It can be used in patient monitoring systems, diagnostic equipment, imaging equipment, and medical robotics, ensuring reliable data transmission and patient safety.

D. Automotive and Transportation In the automotive and transportation industry, for wiring harnesses, vehicle control systems and lighting systems. Its flexibility, chemical resistance, and temperature resistance make it suitable for the harsh conditions encountered in vehicle and transportation applications.

E. Outdoor lighting and power distribution multicore shield cable is usually used in outdoor lighting installations, such as street lighting, architectural lighting and landscape lighting. Its resistance to UV radiation, weather conditions and abrasion ensures long-lasting performance and reliability.

Precautions for choosing UL TPU cable

When selecting a UL TPU cable for a specific application, several factors should be considered:

- Specific Project Requirements and Environmental Factors Understanding project requirements, such as temperature ranges, exposure to chemicals or oils, and mechanical stress, is critical to selecting the appropriate UL TPU cable. Evaluating environmental factors ensures that the characteristics of the cable match the needs of the application.

- Electrical Loading and Power Delivery Requirements Considering electrical loading and power delivery requirements will help determine proper cable size, conductor gauge, and voltage rating. This ensures that the selected multicore shield cable can handle the expected current and power demands without voltage drop or overheating.

- Compliance with Industry Standards and Regulations Verifying that the selected cable complies with relevant industry standards and regulations is critical to safety and reliability. Check for certifications, such as UL Listing or Approval, to ensure the quality of the cable and compliance with industry requirements.

En conclusión

popular ul tpu cable has many key features and advantages that make it the first choice for various industries and applications. Its flexibility, durability, resistance to harsh environments, superior performance and enhanced safety ensure reliable electrical systems and installations. The cable’s compatibility with different electrical systems and equipment, as well as its versatility in fixed and mobile applications, further strengthens its position as a reliable and efficient wiring solution. When selecting cables such as UL 2468 cable vs UL TPU cable, consideration of project requirements, electrical loads, and compliance with safety standards can help ensure optimal performance and long-term reliability.

Anyte Cable no sólo desarrolla y fabrica cables estándar de alta calidad. awm ul2517awm ul20234 y otros cables, sino que también proporciona excelentes soluciones de acuerdo a sus necesidades y aplicaciones de productos. Bienvenido a su consulta en cualquier momento.

Productos relacionados